We use cookies to make your experience better. View our Privacy Policy here to learn more.

AIRCAT Impact Wrench Mechanisms and Performance Characteristics

VIBROTHERM DRIVE™ is a new AIRCAT patented mechanism that provides faster blow frequency, high torque, low vibration and a longer working life than other conventional impact wrench mechanisms. In addition it reduces overall tool length. The cage is driven by the motor that drives the two hammers to generate two blows for each revolution, the elimination of hammer pins and the addition of the front hammer cage plate that retains the grease within the mechanism, reduces wear within the mechanism increasing working life

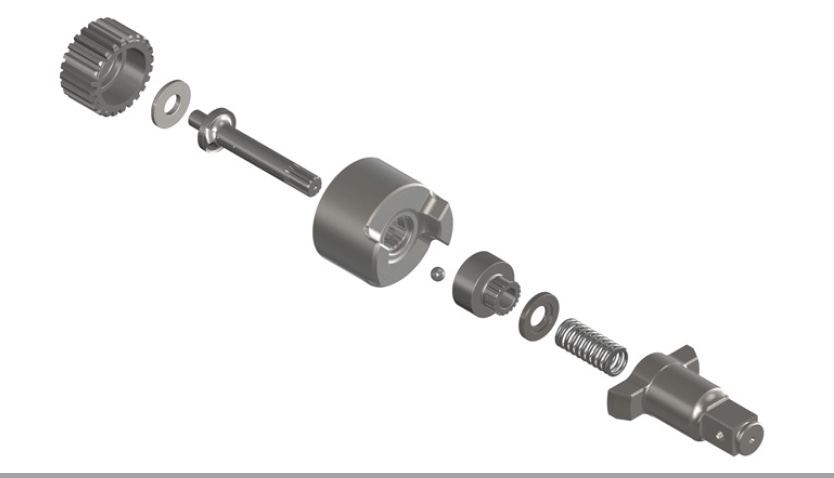

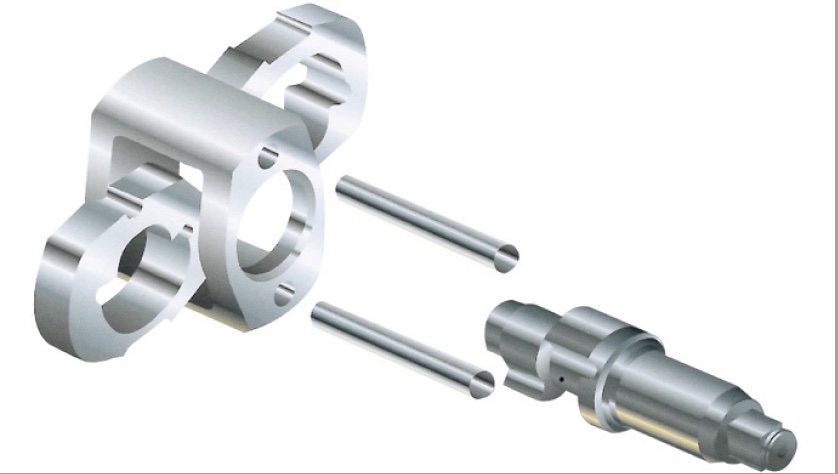

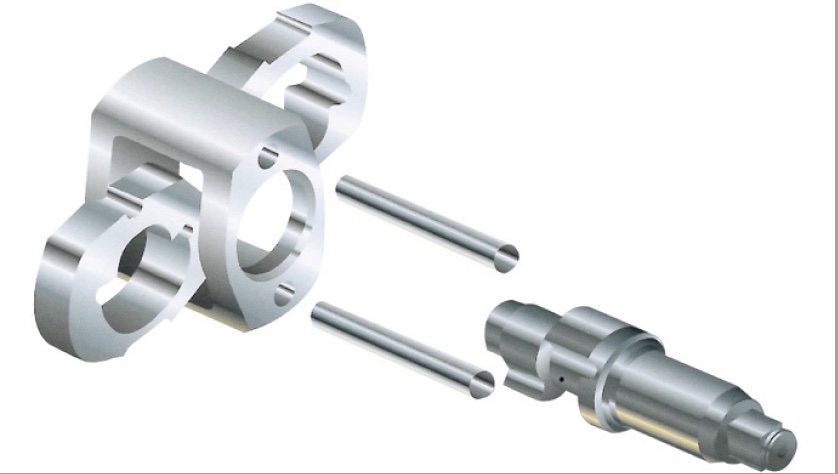

The TWIN HAMMER is the most widely used impact wrench mechanism that provides fast blow frequency and high torque. The mechanism is most widely used for AIRCAT 3/8”, 1/2” and 3/4” impact wrenches. The cage is driven by the motor that drives the twin hammers that rock on hammer pins that pass through the hammer cage to generate two blows for each revolution.

The PIN-LESS HAMMER is used in AIRCAT 1” impact wrenches. The PIN-LESS mechanism has a more positive drive and uses less moving parts, this design increases reliability for heavy duty applications. The large single hammer provides hard hitting power to achieve rapid high torque. The cage is driven by the motor that drives the large single hammer to generate one hard hitting blow for each revolution.

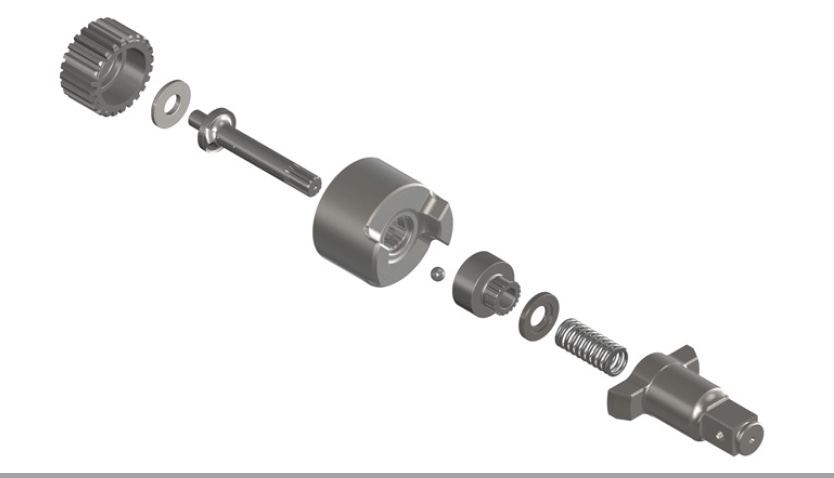

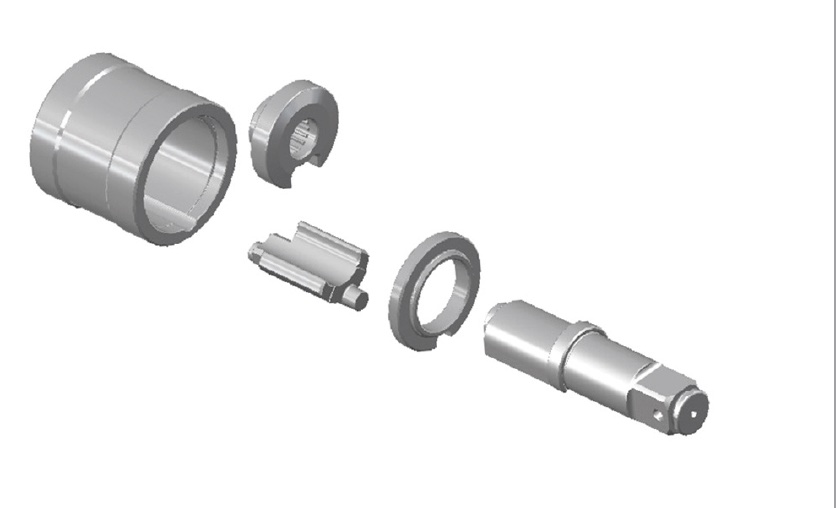

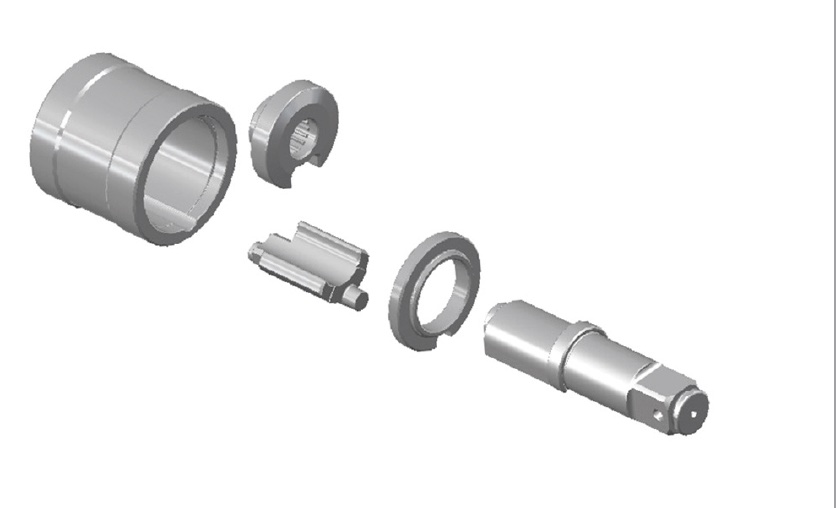

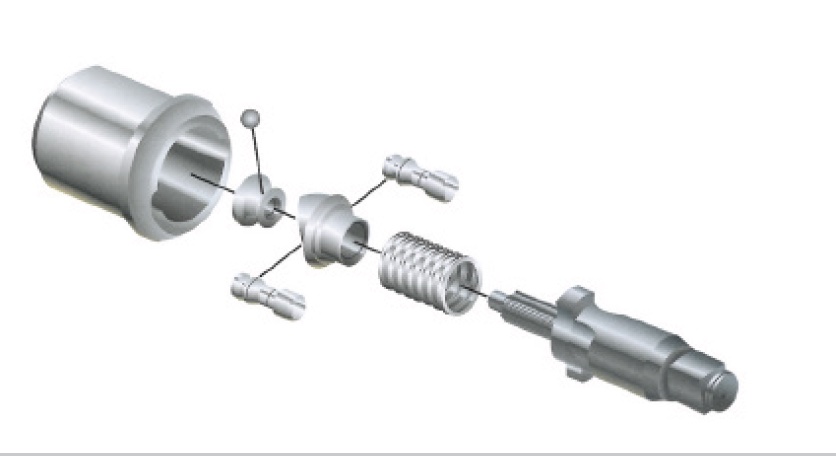

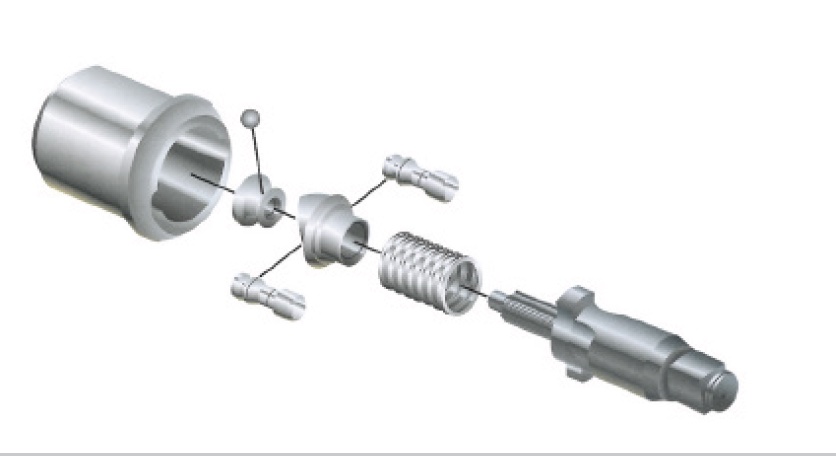

The TWIN CLUTCH is featured in NITROCAT ½” impact wrenches and is specifically designed to provide smooth and powerful operation, and to create high initial torque. This mechanism outperforms other mechanism in high torque engine service and repair work, and particularly for removal of stubborn crank shaft bolts. When the hammer rotates past the anvil a ball pushes the pins forward engaging them with the anvil, the pins are then pushed backwards by the spring, this mechanism has very fast acceleration that creates the high initial toque

The JUMBO HAMMER is used in AIRCAT and NITROCAT compact impact wrenches. The JUMBO hammer enables AIRCAT to provide high torque and high reliability in its smallest impact wrenches. The cage is driven by the motor that drives the single JUMBO hammer that rocks on hammer pins that pass through the hammer cage to generate one hard hitting blow for each revolution.

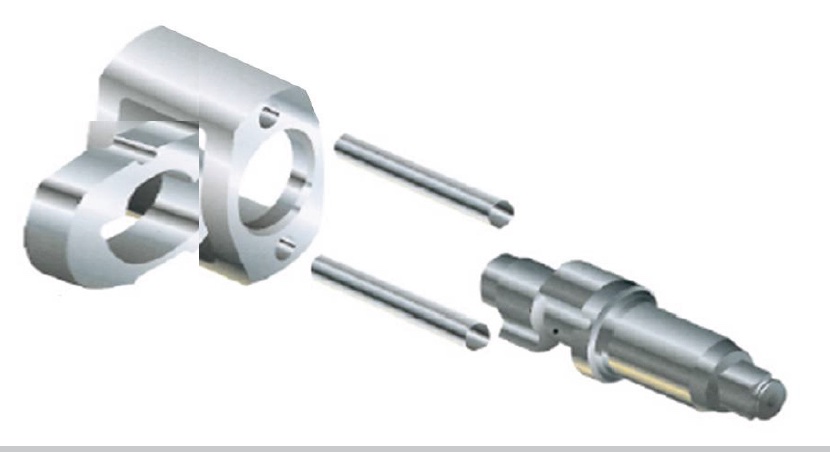

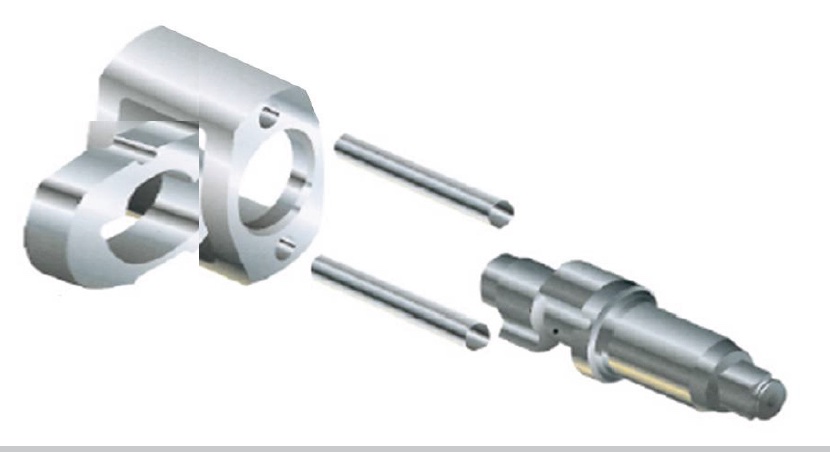

The TWO JAW CLUTCH is featured exclusively in the AIRCAT 1890-P 1” Pistol Grip Impact Wrench. The TWO JAW clutch provides unparalleled torque output and longer life than any other mechanism. The cage is driven by the motor the jaws on the cage directly drives the anvil, this action eliminates the customary hammering increasing torque and reducing wear, the internal spring then disengages the jaws to turn to the next drive cycle. The mechanism is ideal for heavy duty off road vehicle work and steel erection